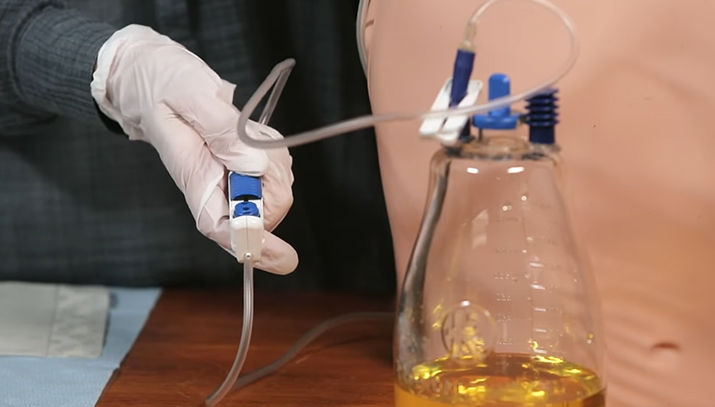

Blow moulding is the preferred option for the manufacture of specialized hollow components, reservoirs and containers for medical, pharmaceutical and diagnostic applications. This versatile process can be utilized to create non collapsing sealed vacuum units, collapsible reagent dispensers or a wide variety of hollow components.

Synecco work with a range of clients in multiple fields, across diagnostics and medical devices, to deliver technically challenging solutions for a wide range of applications

These components must be engineered to withstand robust use and to prevent permeation, discoloration & leakage. With options for thick and thin wall solutions and a range of materials available, expert input in this area is essential.

Synecco technical blow moulding capabilities include;

Extrusion Blow Moulding

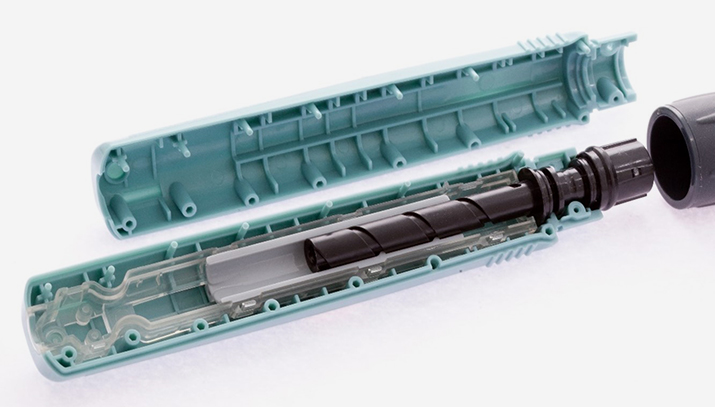

Thick wall Device Components

Reagent Packaging