Synecco offers accredited inspection services through our advanced metrology systems and capabilities. Our dedicated metrology department is responsible for verifying all final products, equipped with various instruments regularly calibrated according to our internal and external calibration plan.

Industrial measurements of components help identify non-conformities before assembly, provide crucial data during pre-series part design and production, and facilitate measurement comparisons between manufacturers and buyers. Our service quality is upheld by our skilled and efficient technicians, backed by extensive experience in metrology and high-quality measurement equipment.

Our Equipment’s include:

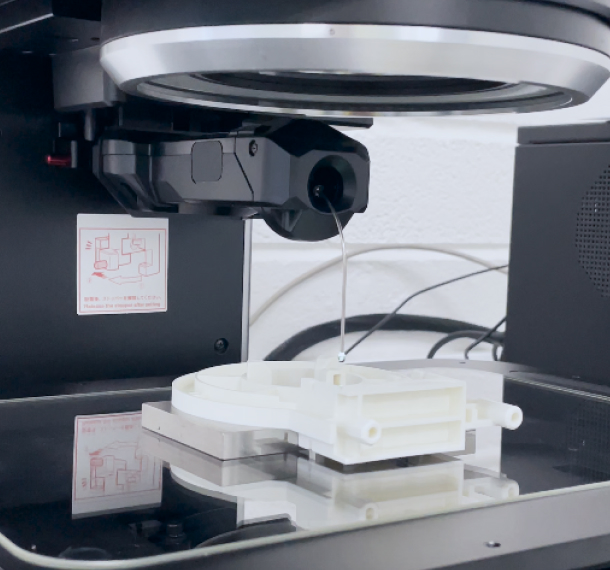

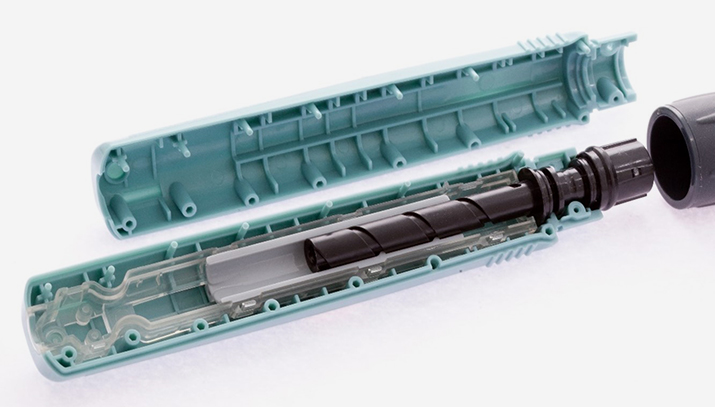

Contactless Vision Measurement System

Measure up to 100 Parts in a single cycle

2 & 3 Jaw Chuck attachment to hold components

Contact Measuring System (CMM)

Moisture Analyser

Digital Toolmakers Microscope

Video Magnifier/Microscope for Quality Inspection Purposes

The services we provide in this area include;

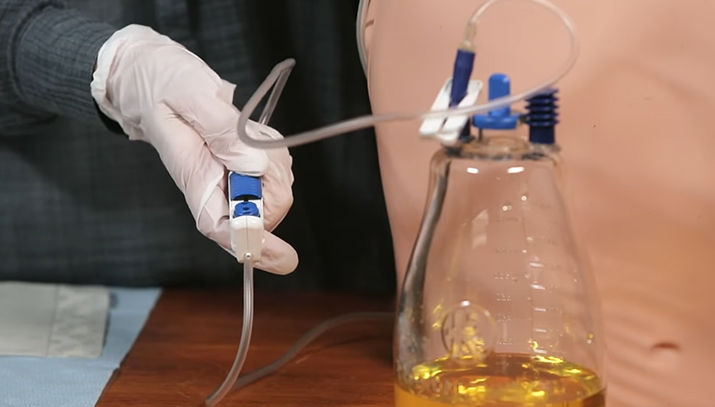

Dedicated Quality Controllers and Metrology Operator

Primary focus being Validation and In-Process Quality Inspection

Materials Testing – Moisture Analysis of Dried Material (%MC Analysis)