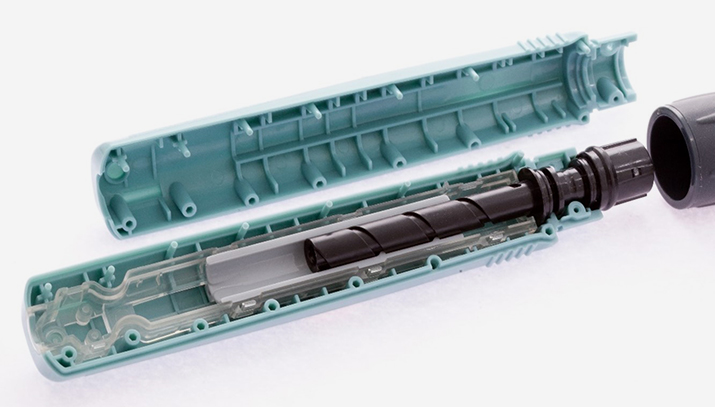

Twin-shot moulding is the process in which two different plastic resins are molded together in a single moulding cycle. Twin-shot injection molding is an excellent technique for efficient and cost-effective molding and assembly process for complex, multi-color, and multi-material plastic products, especially in high-volume production scenarios.

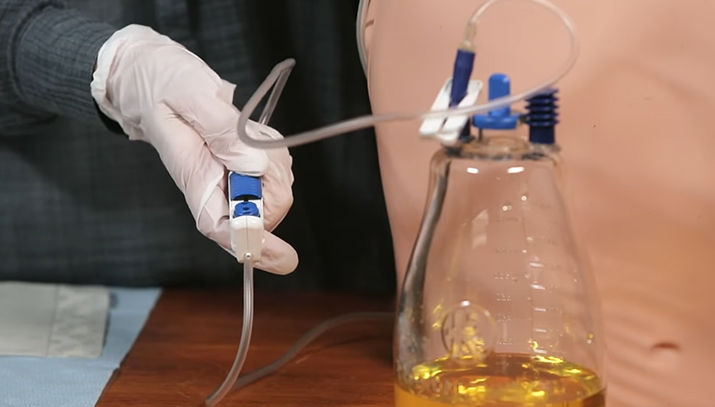

Our service is tailored to assist our customers in optimizing their technical manufacturing process by converting an existing product assembly of two separate parts into a single part. This enhancement provides our clients with several valuable advantages, such as a reduced bill of materials, significantly decreased assembly times, elevated product quality, and an overall improved design, all while achieving cost savings.

Furthermore, we excel in the production of numerous twin-shot products, offering comprehensive support that spans initial product design for manufacturing, tool creation, and injection moulding production.